24 Oct Indirect Heaters

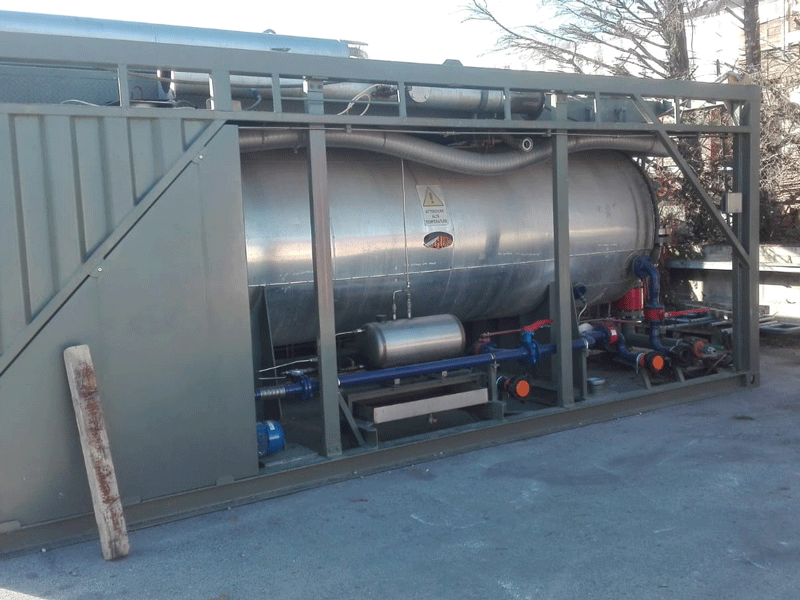

The heaters are of boiler types, that’s to say indirect fire with interposition of water that acts as a means of transmission of heat from the heating fluid (products of combustion) to the fluid to be heated. The burners used on heaters are bicombustibili (natural gas or fuel oil).

The effluent of the well raises its temperature when it goes through the high pressure serpentine Φ 2 “or 3”, located inside the atmospheric vessel and immersed in water.

The heaters are generally used to increase the temperature of the effluent coming from the well, generating multiple effects:

- It compensates for the decrease of the temperature of the effluent as a result of a reduction of pressure;

- Prevents the formation of hydrates

- Improves degassing oil

- Reduces the viscosity of the oil

- Reduces condensation of paraffins and asphaltenes

- Stabilizes the temperature of the separator

- Facilitates the sampling to the separator

- Promotes the breakdown of liquid-liquid emulsions at different specific gravities.

The units are certified PED and H2S service. They are equipped with centrifugal pumps for the circulation of hot water, which runs through a closed circuit, the coils of the equipment of which they are equipped (storage tanks, stabilization separators, etc..) heating the hydrocarbons contained in them.

The heaters are equipped with sensors for the detection of explosive mixtures and for the control of emissions. Connected to a control unit that controls the operation of the boiler and combustion, they have the function of safety and reducing environmental impacts.